Wuxi Weishitiong Machinery Co., Ltd.

Spiral Steel Plate Heat Exchanger,Spiral-Plate Steel Heat Exchanger,High Efficiency Spiral Heat Exchanger

Wuxi Weishitiong Machinery Co., Ltd.

Spiral Steel Plate Heat Exchanger,Spiral-Plate Steel Heat Exchanger,High Efficiency Spiral Heat Exchanger

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Bag/Bags |

Brand: WST

Packaging: npackaged

Productivity: 10000吨

Transportation: Ocean

Place of Origin: Wuxi City,China

Supply Ability: 1000

Certificate: GB ASME PED

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF

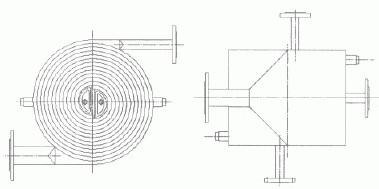

High Efficiency Spiral Stainless Steel Plate Heat Exchanger, Spiral Plate Heat Exchanger is welded by two thin metal plates in a separate baffle and rolled into a spiral. Two thin metal plates in the device to form two spiral channel, in the top and bottom were welded with a cover plate or head.

Spiral Plate Heat Exchanger Structure is shown in Fig:

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Categories : Heat Exchanger