Wuxi Weishitiong Machinery Co., Ltd.

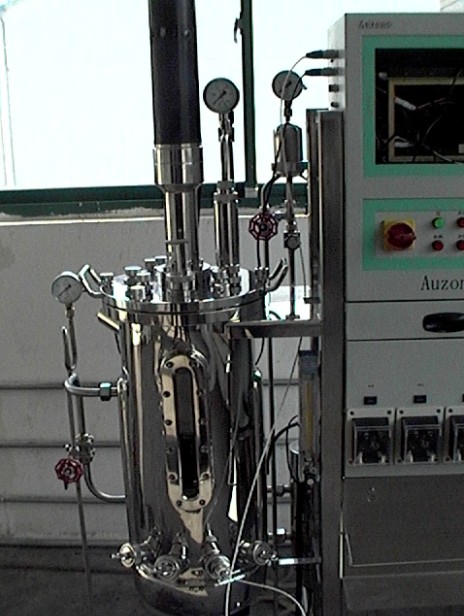

Stainless Steel Fermenter Tank Series,Fermenter Tank Series,30L Fermenter Tank Series

Wuxi Weishitiong Machinery Co., Ltd.

Stainless Steel Fermenter Tank Series,Fermenter Tank Series,30L Fermenter Tank Series

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Bag/Bags |

Brand: WST

Packaging: Seaworthy Packing

Productivity: 1000

Transportation: Ocean

Place of Origin: Wuxi City,China

Supply Ability: 1000

Certificate: GB ASME PED

Port: SHANGHAI

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF

| Nominal capacity (M3) | Diameter cylinder(Dgmm) | High cylinderH(mm) | Heat transfer area M2 | Stir rotational speed r.p.m | Mixing shaft power KW |

| 10 | 1800 | 3800 | 14 | 160-260 | 17-22 |

| 15 | 2000 | 4800 | 18 | 166-260 | 22-30 |

| 20 | 2200 | 5000 | 22 | 180-260 | 30-37 |

| 30 | 2400 | 6600 | 34 | 150-250 | 45-55 |

| 40 | 2600 | 7500 | 45 | 150-250 | 55-75 |

| 50 | 2800 | 8000 | 58 | 150-250 | 55-90 |

| 60 | 3000 | 8300 | 65 | 150-250 | 60-115 |

| 75 | 3200 | 8800 | 84 | 150-250 | 90-145 |

| 100 | 3600 | 9400 | 114 | 150-250 | 120-125 |

| 150 | 4200 | 10800 | 165 | 150-250 | 165-275 |

| 200 | 4600 | 11500 | 220 | 140-240 | 215-360 |

Product Categories : Complete Set Of Equipment