Wuxi Weishitiong Machinery Co., Ltd.

Stainless Steel Shell Heat Exchanger,Stainless Steel Tube Heat Exchange,Stainless Steel Heat Exchanger

Wuxi Weishitiong Machinery Co., Ltd.

Stainless Steel Shell Heat Exchanger,Stainless Steel Tube Heat Exchange,Stainless Steel Heat Exchanger

| Payment Type: | L/C,T/T,Paypal |

|---|---|

| Incoterm: | FOB,CFR,CIF |

Brand: WST

Principle: Mixing Heat Exchanger

Structure Material: Metal Material

Core: Core Evaporative Heat Exchanger

Type: Stainless Steel Heating Equipment

Application: Heater

Style: Steel Type

Ceramic Heating Equipment Type: Ceramic Electric Heater

Mixing Heat Exchanger Type: Cooling Tower

Recuperative Heat Exchanger Type: Shell and Tube Heat Exchanger

Heat Transfer Surface: Tubular Heat Exchanger

Packaging: Unpackaged

Transportation: Ocean

Place of Origin: Wuxi City,China

Payment Type: L/C,T/T,Paypal

Incoterm: FOB,CFR,CIF

6.Xinxiang Jinxin company with the stateadministration of quality supervision, inspection and quarantine issued specialequipment levels A1 (single high pressure),

Structure

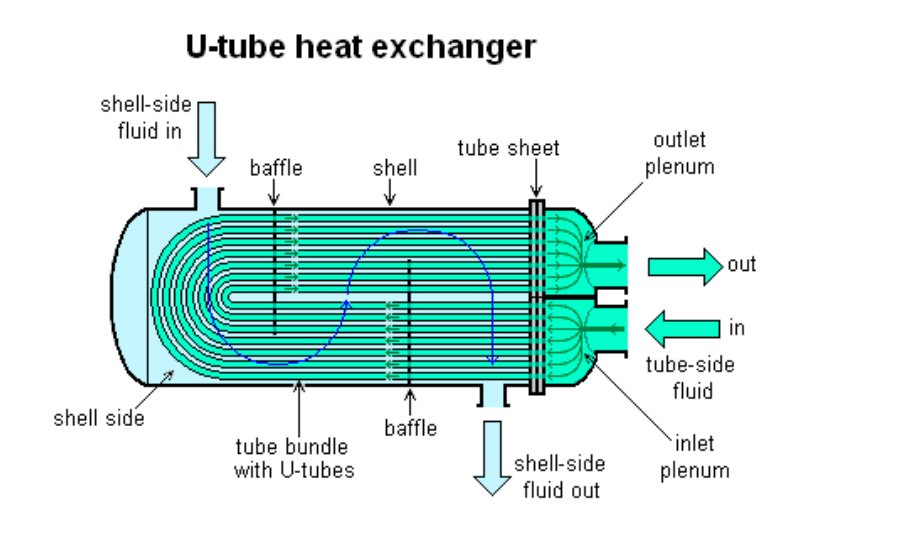

Shell and Tube Heat Exchanger by the shell, heat pipe bundle, tube sheet, baffle (baffle) and tube boxes and other components. Shell is mostly cylindrical, with internal tube bundles, tube ends fixed on the tube plate. Heat transfer of the two hot and cold fluids, one in the tube flow, known as the tube-flow fluid; the other flow in the tube, known as the shell-side fluid. In order to increase the coefficient of heat transfer of the fluid outside the tube, several baffles are usually installed in the housing. The baffle can increase the velocity of the shell side fluid, forcing the fluid to pass through the tube bundle a plurality of times along the prescribed course, and enhance the turbulence degree of the fluid. Heat exchange tube in the tube plate can be arranged in an equilateral triangle or square. Equal triangle arrangement is more compact, the tube outside the high degree of turbulence, heat transfer coefficient; square arrangement is easy to clean the pipe, suitable for scaling fluid.

Each tube through the tube is called a tube; each through the shell is called a shell. In order to improve the fluid velocity inside the tube box can be set in both ends of the partition, all the tubes are divided into several groups. So that the fluid passes through only a portion of the tube at a time, so that it travels several times in the tube bundle, which is called multi-tube. Similarly, in order to improve the flow outside the tube, can also be installed in the shell of the vertical baffle, forcing the fluid several times through the shell space, known as the multi-shell. Multi-tube and multi-shell can be used with the application.

Product Categories : Heat Exchanger