On-dismountable Spiral-plate Heat Exchanger , The removable plate heat exchanger is composed of a plurality of punched corrugated sheets which are sealed at a certain interval by a gasket and are compressed by a frame and a pressing screw. The four corners of the plate and the gasket form a fluid Piping and collecting pipes, and at the same time reasonably separate the hot and cold fluids so as to flow in the flow paths on both sides of each plate, and heat exchange through the plates.

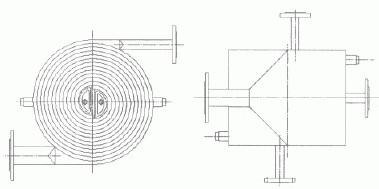

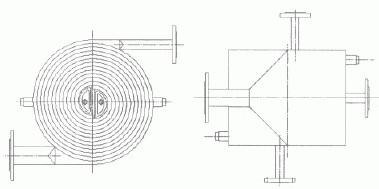

Spiral Plate Heat Exchanger Structure is shown in Fig:

Structure and performance 1. This device is made by rolling to have produced two even helical tubes through which two heat media can full counterflow, enhancing heat exchanging effect. Even with two media of small temp. difference, it also accomplish ideal effect. 2. The body is designed with small resistance. Liquids will not meet sharp turns due to even bend rate of the tube to have reduced resistance, so that the design speed can be raised to reach better exchanging capability. 3. I type inseparable helical exchanger is designed with welded sealing on the end surface of tube, which means excellent tightness. 4. The structural theory of II type separable exchangers is basically the same as that of inseparable one, except that one tube can be disassembled for cleaning, applicable for high viscosity liquids and those with sediment. 5. The structural theory of II type separable exchangers is basically the same as that of inseparable one, except that two tubes can be disassembled for cleaning, applicable for a wider range. 6. The helical exchangers can be divided into PN0.6, 1.0, 1.6 and 2.5MPa (referring to max. bearable working pressure for single tube) according to nominal rating, or carbon steel and stainless steel according to materials. Users can choose according to actual technique parameters. 7. When single set of device is not satisfactory, combination of multiple sets can be used under the following conditions: Same distance between parallel combination, in-series combination, device and tubes. Mixed connection with one tube parallel and other in series.

Features:

Features:

1, recovery of low-temperature heat

The two kinds of fluid flow through the spiral plate on both sides, one of the fluid along the spiral channel from outside to inward to the central outlet outflow; the other fluid is along the spiral channel from the center entrance, from the inside out. The two fluids flow in a pure countercurrent flow, suitable for small temperature difference heat transfer, recovery of low temperature heat, waste heat recovery.

2, low prices

Light weight, the same is a 20m2 heat exchanger tube weight is about 800kg, while the spiral plate is about 480kg. Easy manufacturing, high material utilization, to board hosting, low cost, the use of Coil guarantee quality. The cost of the spiral plate heat exchanger is only 1/2 to 1/3 of that of the tube type heat exchanger.

3, self-cleaning dirt

Medium to take a single channel, allowing flow rate higher than other heat exchangers, the higher the flow rate of the fluid, suspended solids in the fluid is not easy to settle down, and any sediment will reduce the cross-section of a single channel, thus increasing the speed, Blocking area and play the role of erosion, so the spiral plate heat exchanger is not easy to be blocked dirt is not easy deposition. Production practice has proved that the spiral plate heat exchanger is generally compared with the Tube Heat Exchanger is not easy to plug, in particular, sediment, small shells and other suspended particulate impurities in the spiral channel is not easy to deposit.

4, less heat loss

Outer surface area is small, close to normal temperature fluid from the edge of the channel out (into), without insulation.

5, the heat transfer coefficient

Due to the centrifugal force and the interference between the two plates, the turbulence can be reached at low Reynolds number (generally Re = 1400-1800, sometimes as low as 500) due to the rotational movement of the fluid in the spiral channel, and (2m / s for liquid and 20m / s for gas), so the total heat transfer coefficient is about 2 times of that of tube type heat exchanger and the heat transfer efficiency is Tube heat exchanger 1 to 3 times.

6, compact structure

The heat transfer area per unit volume is about three times that of the tube type heat exchanger. For example, a heat transfer area of 100m2 spiral plate heat exchanger, the diameter and height of only 1.3m and 1.4m, the volume of only a few tube heat exchanger. Product Categories : Heat Exchanger